7 Simple Techniques For Laser Scanning Solutions, Llc.

Table of ContentsFacts About Laser Scanning Solutions, Llc. UncoveredHow Laser Scanning Solutions, Llc. can Save You Time, Stress, and Money.Laser Scanning Solutions, Llc. Fundamentals ExplainedExcitement About Laser Scanning Solutions, Llc.

In order to position a laser light beam in 2 dimensions, it is possible either to rotate one mirror along two axes - used generally for sluggish scanning systems - or to reflect the laser beam of light onto 2 carefully spaced mirrors that are installed on orthogonal axes (http://dugoutmugs01.unblog.fr/2023/11/01/unveiling-the-potential-of-3d-laser-scanning-services/). Each of both flat or polygon (polygonal) mirrors is after that driven by a galvanometer or by an electric motor respectively

Lots of laser scanners even more allow transforming the laser strength. In laser projectors for laser Television or laser displays, the three basic shades - red, blue, and green - are combined in a single beam of light and then reflected together with 2 mirrors.

Modern lasers can cut steel blocks with a thickness of 10 centimeters and more or ablate a layer of the cornea that is only a few micrometers thick - https://www.imdb.com/user/ur172208547/.

The Laser Scanning Solutions, Llc. PDFs

That card converts the gotten vector data to activity details which is sent to the scanhead. This scanhead is composed of two mirrors that are able to disperse the laser beam of light in one level (X- and Y-coordinate). The third measurement is - if necessary - recognized by a details optic that has the ability to relocate the laser's prime focus in the depth-direction (Z-axis).

For these situations it is vital that the laser has as tiny a prime focus as feasible (3d laser scanning). For improved laser scanning applications and/or high product throughput during production, scanning systems with more than one scanhead are utilized. Here the software needs to regulate what is done specifically within such a multihead application: it is possible that all available heads have to mark the same to finish processing quicker or that the heads note one solitary work in parallel where every scanhead carries out a component of the work in situation of huge workspace

In these gadgets, a semiconductor laser beam is usually checked with the aid of a powerful mirror scanner. The mirror is driven electromagnetically and is made from a you can check here metal-coated polymer. When a room copyright has to dock to the room terminal, it needs to carefully steer to the correct setting. In order to establish its family member placement to the spaceport station, laser scanners constructed right into the front of the room transporter scan the shape of the room station and afterwards figure out, through a computer, the steering commands.

The usages just noted which are only a small tasting of laser scanning applications have widely differing technological demands. This includes criteria like scanning speed, the size of the area or volume that need to be covered, the laser power involved, the price, size, dependability, and life time of the scanner, and a lot a lot more.

Get This Report about Laser Scanning Solutions, Llc.

Relying on the nature of the job, galvanometer scanners are often utilized in sets. Especially, in this instance they are placed with their scan directions at best angles to each various other. This allows the laser beam of light to reach any factor in a plane. For lots of applications, specialized scan optics, like an F-theta lens, are utilized to focus the light beam on the last surface area.

Going back to 1960, when Theodore Maiman created the first laser, this kind of light has evolved right into a device used across sectors. From clinical treatment to production processing, the power of lasers is made use of throughout a myriad of markets and for several kinds of applications. When most consider lasers, the ubiquitous traffic signal lasers commonly enter your mind.

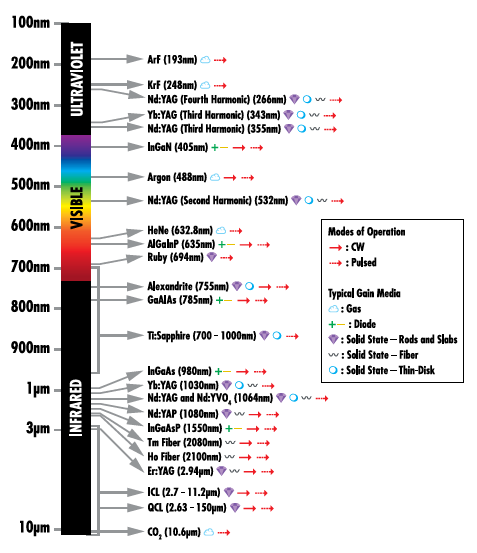

There are over 8 types of lasers across 3 classifications! Light wavelength distribution map Solid-state lasers are kinds of lasers that use a strong material as its gain medium.

See This Report about Laser Scanning Solutions, Llc.

When a laser diode radiates light on the drugged product, the neodymium atoms are delighted and discharge light. This light is then intensified by the material and released as a laser beam.

Gas lasers are utilized for machining and marking applications like marking labels, engraving plastic and resins, processing, and reducing. These laser types utilize gas as the medium rather than a strong or liquid. The four sorts of gas lasers are carbon dioxide, He-Ne, excimer, and argon. Carbon dioxide gas lasers have the lengthiest wavelength compared to fiber, YAG, and YVO4.

Since of the lengthy wavelength, there is more heat transfer than other lasers. Carbon dioxide lasers are frequently made use of for cutting products.